Dry feeding

While for liquid feeding the various components (flour, CCM, whey, silage corn, potato pulp, etc.) get mixed together and can be fed homogeneously, this applies for dry feeding only a very limited way.

From our point of view there are three variations:

1.) The simple variant:

A flour silo close to the pigsty, from where a short auger feeds the flour into the feedstuff pipeline. In the pipeline a chain with cams pulls the flour into the pigsty, where it turns out of taps into the automatic feeder. The amount of feed can be adjusted through telescopic tubes in the feeder. This variant is often extended to a second flour silo in order to completely empty the flour silo prior to a new flour delivery. For this purpose there is a toggle switch which releases the flour screw alternately.

2.) Semiautomatic dry feeding:

From up to four different flour silos the respective type of feedstuff gets transported into the feedstuff pipeline, in a user predetermined order. Each tap of the automatic feeders is operated by compressed air and can be assigned (open/close) to the matching feedstuff type through ball valves. When the first automatic feeders are stuffed with the matching type of feedstuff, the residual stuff in the pipeline is emptied into the origin silo. Subsequently, the other predefined varieties are fed into the tube system, with the appropriate emptying process in between. The quantity control is performed as in the simple variant on telescopic tubes in the automatic feeders.

3.) Automatic dry feeding:

As with a fully automatic liquid feeding, each tap is mounted as a single valve. The amount of feedstuff is determined by a computer program, based on appropriate user data (feed curve, mixture recipe, valve percentages, etc.). The feedstuff is mixed in a weighing container and dispensed as a single dose into the feedstuff pipeline. Now this portion get transported to the respective valve, supported by a distance meter. Meanwhile, the next portion is mixed in the weighing container and dispensed. The feedstuff can either be mixed in a (large-scale) group weighing mixer or in a small-scale mixer. Each automatic feeder can be equipped with a sensor. This sensor ensures that only feedstuff amounts for empty feeders are determined.

Outdoor silos with tandem dry feeding

Drive station TF 60 and infeed/dosing funnel. The contol modul of the dry feeder system actuates two screw conveyors on one infeed/dosing funnel.

All timings regarding start, disturbance and lights are determined on-site by the appropriate parameters.

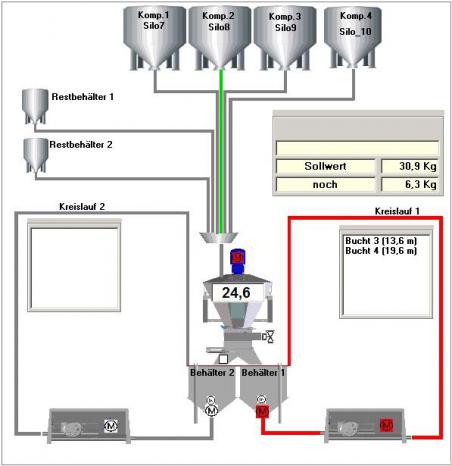

Large scale (group) weighing mixer with multiple components

The feedstuff is mixed via multiple infeed screws which feed the weighing mixer. It then gets dosed in portions into the feedstuff pipeline. The portion is sent exactly to the feed valve - based on a measurement of the conveyor chain length .

It is possible to have multiple portions in one pipeline at the same time. When the last portion of the charge was dosed into the pipeline, then the next mixing process can start immediately.

Fully automated dry feeding with single portion mixer

The feedstuff is mixed in single portions. Then it falls into a dispensing container underneath the mixer. From there it is discharged into the feedstuff pipeline. Meanwhile, the mixer in the tank prepares the next mixture. This can be done simultaneously for up to 4 lines. This results in a time advantage.

Semiautomatic dry feeding from up to four different silos

Drive station TF 60 and infeed/dosing funnel. The control modul actuates four screw conveyor. All timings regarding start, disturbance and lights are determined on-site by the appropriate parameters